Procestimator

The Procestimator is a decision support tool to assess potential valorization pathways on their pre-feasibility. The tool helps users identify feasible zero waste pathways, by assessing the potential of upscaling fruit and vegetable side streams which reduce FLW.

Considering the composition, volume, availability, structure and microbial and enzymatic stability of specific fruit and vegetable side streams, the tool supports users by:

- providing an overview of the required processing steps to transform the side stream into the aspired end-product;

- providing an overview of the costs of these steps;

- and by computing the nutritional value of the end-product.

To facilitate feasibility studies in a consistent and complete manner the tool uses databases with inherent properties of side streams and expert knowledge on a broad range of processes. The tool is not intended as a detailed process design tool, but instead focusses on the overall picture, so that the critical aspects of a processing scenario in terms of performance and costs will emerge.

How does the tool work?

Procestimator appears to the user as a simplified process flow sheeting tool. For a given choice of input streams and process sequence, procestimator will show the cumulative effect on composition, value and costs, as well the details for each intermediate stream and process.

The starting point is an input stream, which is defined by the volume, a basic composition break-down, concentration of minor components of interest, but also characterizing parameters such as the structure and various quality properties. Via a dialog, an initial selection can be made from databases of food products and side-streams for the feed sector.

Next, successive unit processes are added to get the required product transformation. Each process is characterized by specific key parameters / choices that determine its output streams, capacity, resource requirements and costs. Procestimator contains a collection of simplified process models for which default parameters are provided. For the cost estimation, the availability of process can be varied from installed to green field, or external tolling when available. Also, operations such as (cold) storage, packing and transport are included to complete the overall cost estimation.

What type of insights does the methodology generate?

- Lay-out possible process routes to turn a by-product stream into valuable ingredients.

- Calculating mass balances to end-product compositions and estimate their feed values.

- Estimate of the required process resources, cost and CO2 footprint.

- A cost break-down on process step level

- Result on the effect of a different process set-ups (variation analysis to aid optimization and scenario comparison)

- Feasibility analysis and process solutions

What type of questions does the methodology help respond?

- Which of a pre-selected number of valorisation pathways and scenarios is promising?

- Could my valorisation pathway design be potentially economically feasible?

- What are the critical process steps of my valorisation pathway design?

- Can I improve the economic or environmental impact of my current valorisation process or design?

At what stage can the tool be applied?

The tool is designed to facilitate pre-feasibility studies once data on volumes, quality, local restrictions of specific product streams and its possible valorization routes are known. For promising FLW reducing interventions, the results of the tool can be improved during the project by overwriting the model’s default data with experimental results or more detailed field data.

Link to publication

Case example: Calculation of different options for using banana side streams for different end-products

At farms in Mexico, that produce a specific variety of bananas for the export market, large side streams of rejected bananas are created to fulfil all the export quality demands. With interviews at several farms, information was retrieved on the volumes, current destination and the cost or benefits incurred from these reject streams.

Using the procestimator tool, three alternative valorization destinations were investigated for these rejects, namely: banana flour, chips, and puree.

Output of the procestimator

The procestimator generated three major outputs:

- composition of the end products;

- cost price including a breakdown of the different process steps;

- and the Greenhouse Gas emissions disaggregated for each process step.

Table 1.1 to 1.2 shows example of these tree outputs for the example of production of banana flour.

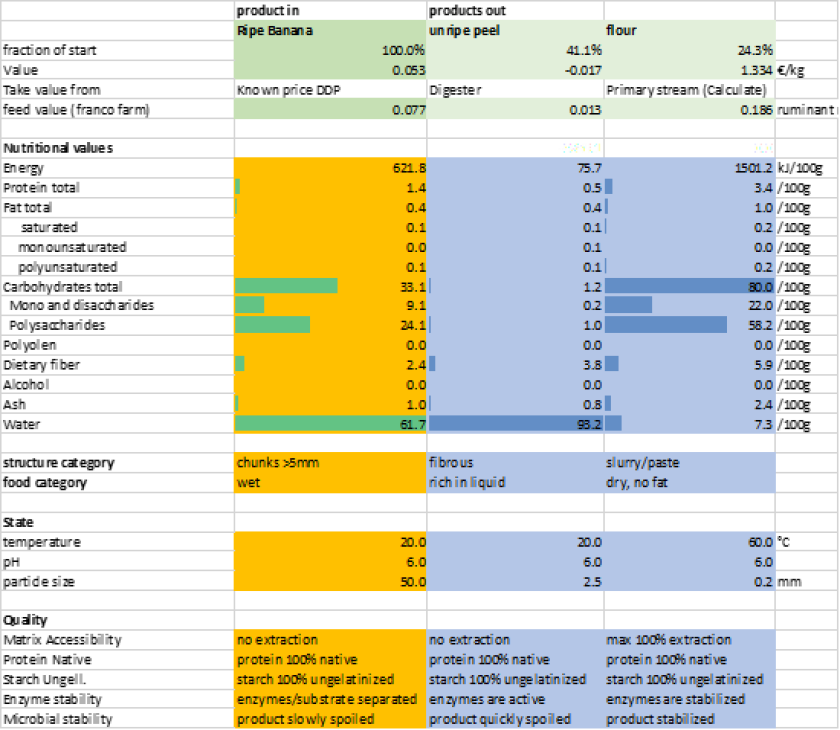

Table 1.1 Composition and (quality) state of the raw material and its main end-products.

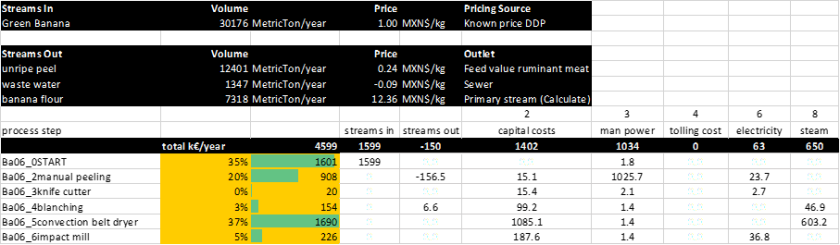

Table 1.2 Cost break down for the production of Banana flour for the lowest cost price based on parameters from farmers interviews.

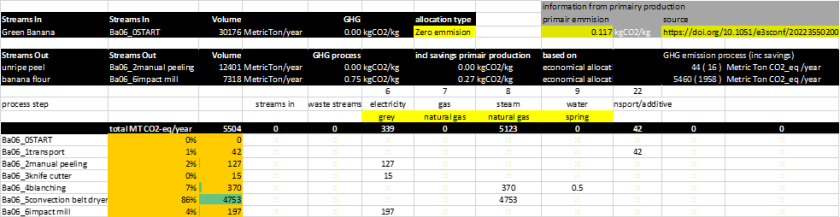

Table 1.3 GHG-emmission break down to produce Banana flour.

Evaluation of the calculations

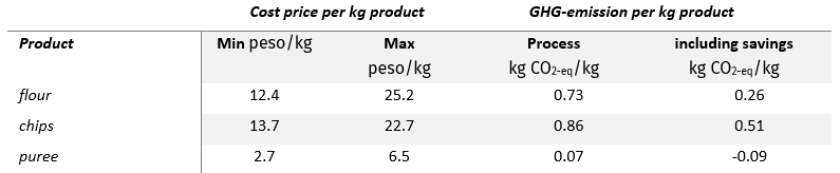

After setting up the process, schemes the different process input parameters can easily be changed to evaluate the effect on the cost price. Think for instance about modifying the available volumes, but also think of modifying prices for different raw materials, raw material composition or discharge costs of any residues. With the maximum and minimum parameter values, the processing costs and GHG-emission were calculated for the different end products, see table 2. With these numbers the feasibility of the different products can be assessed by comparing those numbers with the current market prices and available market size.

As the end-products have different applications, comparison between the products based on the cost price itself is, in this case, less useful. Looking at the GHG-emissions, the production of banana puree could be favorable with respect to reducing GHG-emissions. Additional processing will always add GHG emission, nevertheless, for the banana puree the savings of GHG emissions by reducing the primary production is higher when compared to the emission for the production itself. Therefore, the puree is the only product that could be calculated with a negative GHG emission impact.

Table 2 The min and max cost prices and GHG emissions to produce banana flour, chips and puree from reject bananas based on parameters from farmers interviews

Do you have questions about using this tool?

We are happy to help. Please fill out the contact form and we will get back to you soon.